Good idea with the candle; I definitely never thought of that! I'm anxious to cook that water out but not anxious for freezing weather.

On a separate note, I had a bunch of young adults over at the house last week and one of them saw the RMH book laying on the coffee table and asked if I was interested in building one. Turns out he used to live in some kind of eco-village and has built several of them. He was stoked about my stove and gave me a good lesson in making earthen plaster to cover (he had the recipe in his back pocket). Small world. Ha!

6" RMH Build

Moderator: matt walker

Re: 6" RMH Build

"Knowledge is power. Arm yourself."

-

mannytheseacow - Posts: 942

- Joined: Sun Feb 24, 2013 12:40 am

Re: 6" RMH Build

Would you like to share his recipe with us? I would love to here it.  That has been a draw back for me, never having built with cobb. It would be nice to have a recipe for the plaster that works well.

That has been a draw back for me, never having built with cobb. It would be nice to have a recipe for the plaster that works well.

Never doubt that a small group of dedicated people can change the world, indeed it is the only thing that ever has.

-

pa_friendly_guy - Posts: 1502

- Joined: Sun Jan 08, 2012 9:24 pm

- Location: SW Pa They changed me to zone 6a what ever that is. I still figure zone 5

Re: 6" RMH Build

Sure, The recipe itself is about what Matt shared with me earlier, but the individual explanation from a real person- in-person- was priceless.

1- 5 gallon clay

*slake in buckets with water, to cover, at least 24 hours.

*mix with paddle mixer (on a drill, through the lid of a bucket to prevent splashing)

*Sieve: 1/8" hardware cloth.

3- 5 gallon bucket sand

*sieve: 1/8" hardware cloth or window screen

1/2- 5 gallon bucket manure, fresh or aged, if dry hydrate for a while, -OR-

~1/2 gallon Wheat Paste: Mix white flour and water 50/50 (4 cups-4 cups)

*heat slowly until thickened.

3-4 handfuls of fiber (cattail fluff or fine chopped straw)

*fluff fiber with a weed wacker

*filter through hardware cloth

Mixing: Add water while stirring to ease mixing. Thick slurry is ideal

Application: thoroughly moisten base plaster or cob several times with a sprayer, spray on by hand, trowel smooth from top down, adding plaster by trowel as necessary. After 1-3 hours burnish out trowel marks with cloth. Burninsh 2 -3 times during drying.

1- 5 gallon clay

*slake in buckets with water, to cover, at least 24 hours.

*mix with paddle mixer (on a drill, through the lid of a bucket to prevent splashing)

*Sieve: 1/8" hardware cloth.

3- 5 gallon bucket sand

*sieve: 1/8" hardware cloth or window screen

1/2- 5 gallon bucket manure, fresh or aged, if dry hydrate for a while, -OR-

~1/2 gallon Wheat Paste: Mix white flour and water 50/50 (4 cups-4 cups)

*heat slowly until thickened.

3-4 handfuls of fiber (cattail fluff or fine chopped straw)

*fluff fiber with a weed wacker

*filter through hardware cloth

Mixing: Add water while stirring to ease mixing. Thick slurry is ideal

Application: thoroughly moisten base plaster or cob several times with a sprayer, spray on by hand, trowel smooth from top down, adding plaster by trowel as necessary. After 1-3 hours burnish out trowel marks with cloth. Burninsh 2 -3 times during drying.

"Knowledge is power. Arm yourself."

-

mannytheseacow - Posts: 942

- Joined: Sun Feb 24, 2013 12:40 am

Re: 6" RMH Build

Just got finished reading through this thread and like Matt i am also worried about your exhaust plenum being restricted.

Thanks for referring Ray to my build by the way...although i'm not sure if he looked at it.

In my build i was worried after reading extensively online about the exhaust area from the drum being a trouble point, so i made it as big and free-flowing as i was able to. I tend to draft up my builds before i ever start building, and this helps me spot problems.

I'd be pulling it back apart (again i mean, i saw you tried to) and enlarging that spot even if i had to move some stuff around.

You've got a 6" system where i had an 8", yet you've got more ducting length than i did (which is good, i needed more but didn't have the space), so your exhaust temps at the masonary column should be really low. Which is what made me cringe seeing how you ran the copper water line down close to the stovepipe. That will carry away even more of what little necessary heat remains.

If there was ANY way to run an insulated 6" pipe straight up through the building, or to slide something insulated down from the roof end of the masonary column, i'd do that, so as to keep the exhaust temps high enough. With the good long run of duct inside the mass you have, i'd start the insulated pipe right where it exits the bench.

I'm afraid your gonna have that tall column of exhaust gasses cool off enough to just stop rising and choke the thing down. In my opinion that's what gave you a campfire after the drum heated up. I understand the desire to trap ALL the "wasted" heat, but these heaters do that very well already, and that heat is necessary at that location to make the thing breathe properly. I packed cellulose insulation between my 8" exhaust ducting and a homemade 10" duct to keep the cold outside air from chilling the exhaust pipe above the roof, cause i got sticker shock when i looked at insulated stovepipe prices in my local hardware store.

Other than that i love the look of the brick, i think an unpainted drum looks great (mine turned dark rainbow colors), and i like the water line buried in the mass. I've been thinking of doing that with my new build (still in the planning stages), but being poor i think i'll use 1/2" EMT conduit instead of copper pipe.

Thanks for referring Ray to my build by the way...although i'm not sure if he looked at it.

In my build i was worried after reading extensively online about the exhaust area from the drum being a trouble point, so i made it as big and free-flowing as i was able to. I tend to draft up my builds before i ever start building, and this helps me spot problems.

I'd be pulling it back apart (again i mean, i saw you tried to) and enlarging that spot even if i had to move some stuff around.

You've got a 6" system where i had an 8", yet you've got more ducting length than i did (which is good, i needed more but didn't have the space), so your exhaust temps at the masonary column should be really low. Which is what made me cringe seeing how you ran the copper water line down close to the stovepipe. That will carry away even more of what little necessary heat remains.

If there was ANY way to run an insulated 6" pipe straight up through the building, or to slide something insulated down from the roof end of the masonary column, i'd do that, so as to keep the exhaust temps high enough. With the good long run of duct inside the mass you have, i'd start the insulated pipe right where it exits the bench.

I'm afraid your gonna have that tall column of exhaust gasses cool off enough to just stop rising and choke the thing down. In my opinion that's what gave you a campfire after the drum heated up. I understand the desire to trap ALL the "wasted" heat, but these heaters do that very well already, and that heat is necessary at that location to make the thing breathe properly. I packed cellulose insulation between my 8" exhaust ducting and a homemade 10" duct to keep the cold outside air from chilling the exhaust pipe above the roof, cause i got sticker shock when i looked at insulated stovepipe prices in my local hardware store.

Other than that i love the look of the brick, i think an unpainted drum looks great (mine turned dark rainbow colors), and i like the water line buried in the mass. I've been thinking of doing that with my new build (still in the planning stages), but being poor i think i'll use 1/2" EMT conduit instead of copper pipe.

Darrell "Jake" Jacob, Oddmar on all the forums, KC9PZN to all you amateurs.

-

Oddmar - Posts: 56

- Joined: Sun May 27, 2012 3:08 pm

- Location: Near Arkadelphia, Arkansas

Re: 6" RMH Build

Hey! Oddmar stopped by for a visit!

Thanks for reading so attentively, Oddmar; and thanks for your input. I've been worried about my build. I've had a couple of fires and I've had some smoking issues every time. After trying Matt's suggestion of using candles and priming with newspaper things have been MUCH better, though I still have some problems. Sometimes the draw seems to be okay but then the fire will creep up the feed and towards the end I'll have problems. It seems that the stove just isn't all that "rockety".

The caveat is that I don't want to worry too much because there has never been even a 10* difference between the outside air temp and the air temp in the basement where my stove is. Not to mention, the bench is still wet, and my attic is probably staying pretty hot. So, I'm hoping (foolishly perhaps) that things will work out once the temperature drops. But I am a bit of a worry-wart anyway.

Perhaps the plenum area should be bigger, but honestly I don't think it can be any bigger, so I might just have to live with it. We'll see.

As for insulating all the pipe, I could easily get up in my attic and fill the space between the stove pipe and the masonry column with zonolite, but I was actually thinking rather than insulating it I want to increase the heat transfer from the pipe to the column. As I think I've said somewhere along the threads, that column has done a fine job in heating my upstairs for years, and I really depend on the heat from that to keep us warm upstairs. One of my big fears with the RMH is that I'll be losing all that heat in the column that I used to get with my old potbelly. I've thought of shortening the pipe run through the bench... and I suppose I will if I have to. We'll see how it works first. If worse comes to worse, I can hook my potbelly back up in about 15 minutes flat.

Insulating that section between the bench and the column might not be a bad idea. I might start there if I have problems. I don't forsee the copper pipes being a problem at all. I'm going to put some insulation around those at some point but I really doubt that they will take any significant heat away from the exit flue.

So really what I'm thinking, heating with wood my place never gets below 70*. If it's 50* or lower outside, isn't that temperature differential always going to be enough to keep a good draw? I mean, a good 5 months of the year it's below freezing outside up here!

Eh, we'll make it work. Time for me to go relax and have a homebrew. Thanks for sharing your thoughts, Oddmar. I really appreciate your input!

Thanks for reading so attentively, Oddmar; and thanks for your input. I've been worried about my build. I've had a couple of fires and I've had some smoking issues every time. After trying Matt's suggestion of using candles and priming with newspaper things have been MUCH better, though I still have some problems. Sometimes the draw seems to be okay but then the fire will creep up the feed and towards the end I'll have problems. It seems that the stove just isn't all that "rockety".

The caveat is that I don't want to worry too much because there has never been even a 10* difference between the outside air temp and the air temp in the basement where my stove is. Not to mention, the bench is still wet, and my attic is probably staying pretty hot. So, I'm hoping (foolishly perhaps) that things will work out once the temperature drops. But I am a bit of a worry-wart anyway.

Perhaps the plenum area should be bigger, but honestly I don't think it can be any bigger, so I might just have to live with it. We'll see.

As for insulating all the pipe, I could easily get up in my attic and fill the space between the stove pipe and the masonry column with zonolite, but I was actually thinking rather than insulating it I want to increase the heat transfer from the pipe to the column. As I think I've said somewhere along the threads, that column has done a fine job in heating my upstairs for years, and I really depend on the heat from that to keep us warm upstairs. One of my big fears with the RMH is that I'll be losing all that heat in the column that I used to get with my old potbelly. I've thought of shortening the pipe run through the bench... and I suppose I will if I have to. We'll see how it works first. If worse comes to worse, I can hook my potbelly back up in about 15 minutes flat.

Insulating that section between the bench and the column might not be a bad idea. I might start there if I have problems. I don't forsee the copper pipes being a problem at all. I'm going to put some insulation around those at some point but I really doubt that they will take any significant heat away from the exit flue.

So really what I'm thinking, heating with wood my place never gets below 70*. If it's 50* or lower outside, isn't that temperature differential always going to be enough to keep a good draw? I mean, a good 5 months of the year it's below freezing outside up here!

Eh, we'll make it work. Time for me to go relax and have a homebrew. Thanks for sharing your thoughts, Oddmar. I really appreciate your input!

"Knowledge is power. Arm yourself."

-

mannytheseacow - Posts: 942

- Joined: Sun Feb 24, 2013 12:40 am

Re: 6" RMH Build

I for one would not worry. Try the stove when its cold out fist before you get excited. I do not think that the water pipes will take that much heat away. As you run the pipe upstairs I would consider running another air pipe along the exit pipe though the cob to the 2nd floor. I wonder if you run a separate air pipe from the cobb to the 2nd floor if you wouldn't get a nice gravity air flow heat source. I am not saying that it will work, I am saying that I have always wondered if that would work. And I would love to have a Guiney Pig to try it and see.

Never doubt that a small group of dedicated people can change the world, indeed it is the only thing that ever has.

-

pa_friendly_guy - Posts: 1502

- Joined: Sun Jan 08, 2012 9:24 pm

- Location: SW Pa They changed me to zone 6a what ever that is. I still figure zone 5

Re: 6" RMH Build

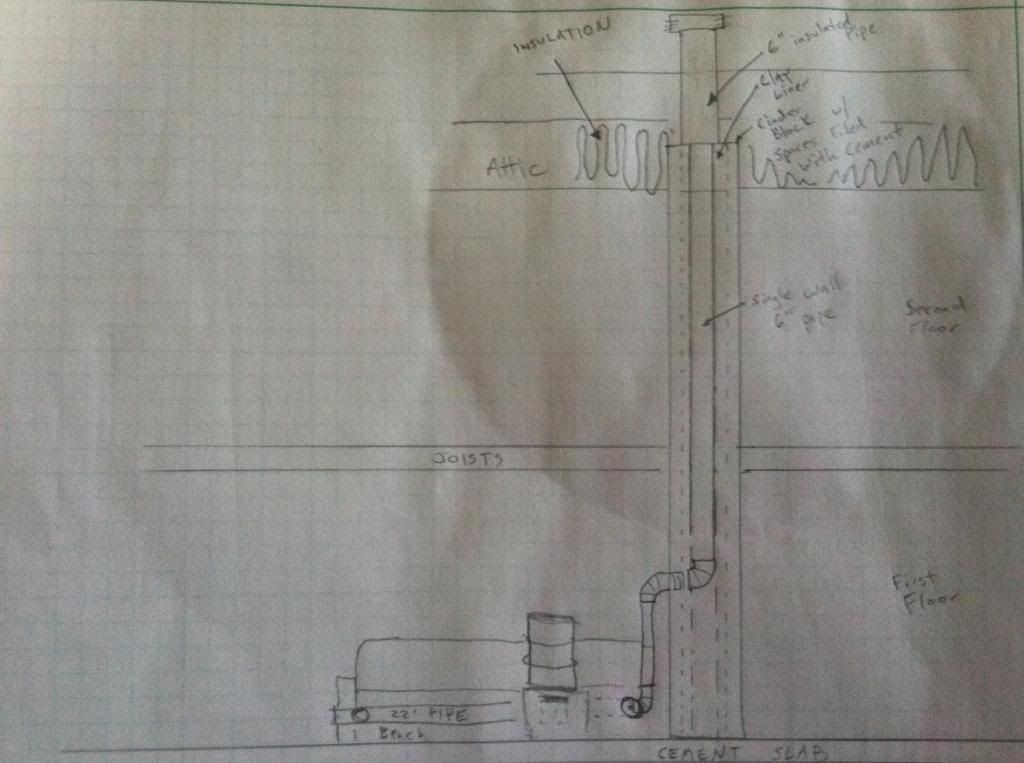

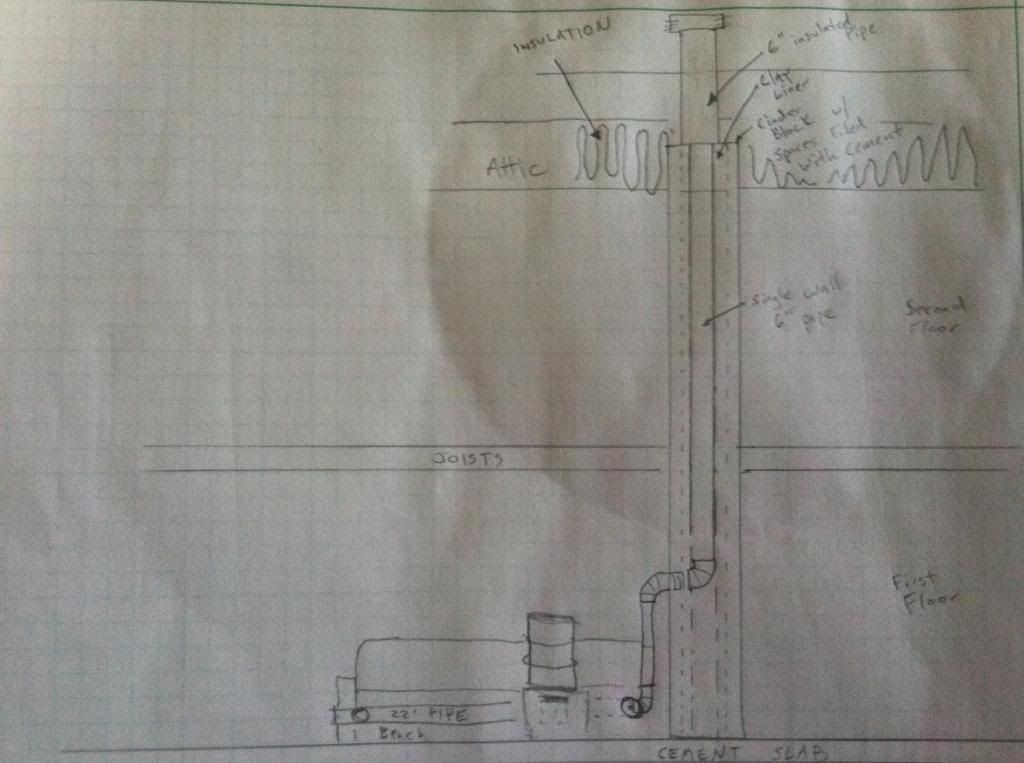

This is a poor drawing but I included it just to be a little more clear on my particular setup.

The vertical run is about 16'.

[quote="pa_friendly_guy"]As you run the pipe upstairs I would consider running another air pipe along the exit pipe though the cob to the 2nd floor.

[As you run the pipe upstairs I would consider running another air pipe along the exit pipe though the cob to the 2nd floor/quote]

I'm not sure what you mean here, Guy? I'm probably missing something (it's been known to happen!)

The vertical run is about 16'.

[quote="pa_friendly_guy"]As you run the pipe upstairs I would consider running another air pipe along the exit pipe though the cob to the 2nd floor.

[As you run the pipe upstairs I would consider running another air pipe along the exit pipe though the cob to the 2nd floor/quote]

I'm not sure what you mean here, Guy? I'm probably missing something (it's been known to happen!)

"Knowledge is power. Arm yourself."

-

mannytheseacow - Posts: 942

- Joined: Sun Feb 24, 2013 12:40 am

Re: 6" RMH Build

I think Guy is talking about a passive register to allow warm air to flow up to the second story. Yeah Guy?

As for draft, mine smokes on the first start up of the season, then runs perfectly all season long. FWIW, my old box stove smoked every time I put wood in, so I consider this a huge improvement. I expect yours will stabilize and run great once everything is warm Manny. You'll have the mass of the bench, then the masonry chimney, all working for you once they are warm.

As for draft, mine smokes on the first start up of the season, then runs perfectly all season long. FWIW, my old box stove smoked every time I put wood in, so I consider this a huge improvement. I expect yours will stabilize and run great once everything is warm Manny. You'll have the mass of the bench, then the masonry chimney, all working for you once they are warm.

-

matt walker - Site Admin

- Posts: 1806

- Joined: Tue Jan 03, 2012 5:50 pm

- Location: North Olympic Peninsula

Re: 6" RMH Build

Hmmm..... like a floor register.... right! I get it now! Sorry I was a little slow on that one. I've actually got the perfect spot for one of those old midwestern cast iron floor registers. I've been looking for one for years and I totally think it's the way to go. Just got to find one in my price range (free).

But yeah, I'm not really worried. Oddmar got me thinking different build options but I think the group here has kept me on track all along. Thanks again for everyone's input. 10 sets of eyes are better than 1!

But yeah, I'm not really worried. Oddmar got me thinking different build options but I think the group here has kept me on track all along. Thanks again for everyone's input. 10 sets of eyes are better than 1!

"Knowledge is power. Arm yourself."

-

mannytheseacow - Posts: 942

- Joined: Sun Feb 24, 2013 12:40 am

Re: 6" RMH Build

At the risk of sounding like a nagging doom-sayer...

You are confusing a RMH with your old potbelly (stove...lol).

The chimney of the old stove (the engine which makes the stove run) is the exhaust pipe. It needs to be fairly hot so the hot exhaust gasses will rise and draw in fresh combustion air.

When you put your water-heating coil on the old chimney, it cooled the pipe too much, increasing creasote production and lessening the draft, right?

In the RMH, the chimney is the heat riser inside the drum, and to a lesser extent the drum itself. Freaky-hot gas shoots upwards inside the heat riser, then expands out inside the drum. Expanding gas cools. The drum leaches heat from the gas. This helps pull the gas Down, kind of a reverse convection. Both these processes suck fresh combustion air in the feed chamber like crazy.

Then the gas, having cooled to 350-400°F, enters the looped ducting inside the thermal mass. This leaches more heat from the gas, until where the gas exits the mass the temperature has fallen to 100-120°F? That's why you can put your hand on the exhaust pipe an hour after starting the stove without burning yourself.

Now YOUR cool gas enters a masonary column which sucks the last bit of heat out of it, and it stops rising. It just hangs there blocking the air coming along behind it. This chokes the RMH and it begins to run slower, then fire creeps back along the fresh wood in the feed chamber, and you have smoke and flame coming into the room.

My RMH ran fine on a 80°F hot day...the cabin air hot from the sun beating down on the roof, when i was showing it to interested locals. This was with the mass still wet because i got a really late start, finishing the build at the END of the heating season.

A pitshure is wurth a ssshouthand wordtth...

You are confusing a RMH with your old potbelly (stove...lol).

The chimney of the old stove (the engine which makes the stove run) is the exhaust pipe. It needs to be fairly hot so the hot exhaust gasses will rise and draw in fresh combustion air.

When you put your water-heating coil on the old chimney, it cooled the pipe too much, increasing creasote production and lessening the draft, right?

In the RMH, the chimney is the heat riser inside the drum, and to a lesser extent the drum itself. Freaky-hot gas shoots upwards inside the heat riser, then expands out inside the drum. Expanding gas cools. The drum leaches heat from the gas. This helps pull the gas Down, kind of a reverse convection. Both these processes suck fresh combustion air in the feed chamber like crazy.

Then the gas, having cooled to 350-400°F, enters the looped ducting inside the thermal mass. This leaches more heat from the gas, until where the gas exits the mass the temperature has fallen to 100-120°F? That's why you can put your hand on the exhaust pipe an hour after starting the stove without burning yourself.

Now YOUR cool gas enters a masonary column which sucks the last bit of heat out of it, and it stops rising. It just hangs there blocking the air coming along behind it. This chokes the RMH and it begins to run slower, then fire creeps back along the fresh wood in the feed chamber, and you have smoke and flame coming into the room.

My RMH ran fine on a 80°F hot day...the cabin air hot from the sun beating down on the roof, when i was showing it to interested locals. This was with the mass still wet because i got a really late start, finishing the build at the END of the heating season.

A pitshure is wurth a ssshouthand wordtth...

Darrell "Jake" Jacob, Oddmar on all the forums, KC9PZN to all you amateurs.

-

Oddmar - Posts: 56

- Joined: Sun May 27, 2012 3:08 pm

- Location: Near Arkadelphia, Arkansas

Who is online

Users browsing this forum: No registered users and 7 guests